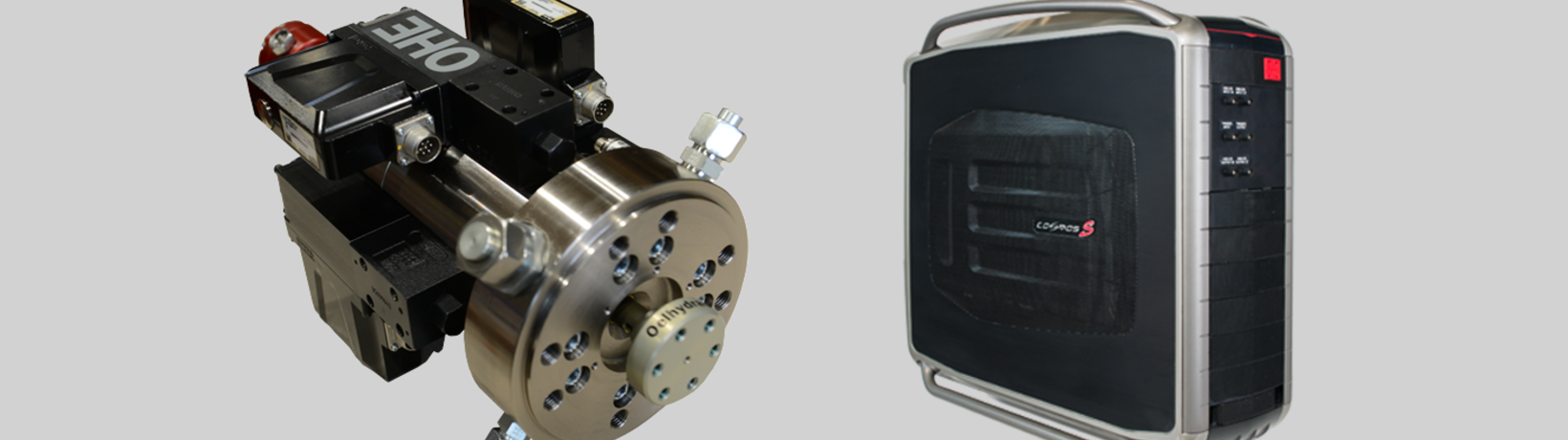

High-Performance-Shaker drive concept

The High-Performance-Shakers were developed to further expand the limits of traditional hydraulic shakers. The drives allow high frequencies up to 600 Hz can be achived, peak accelerations up to 200 g and with useful loads up to 50 kg. The drives have proven effective primarily in the automotive and aviation technology in the testing area.

The drives have fully hydrostatic bearings. This means that pistons are always floating on a oil film. This reduces the friction considerably and most importantly there is no bothersome stip-slick effect. With such high accelerations, the moving mass is the deciding factor. This means that as little own mass as possible must be moved and the force befits the useful load as much as possible. Thus, high-tech materials from aviation and aeronautics are used for all moving parts.

The dimensions of the drives are adapted to customer requests, so that the goals in terms of useful load, peak acceleration and the frequency range can be reached. The shakers can be supplied completely with hydraulic supplies, control electronics, software, safety technology etc.

Technical specifications

|

|

HPS-26-20-20-20 / 50 | HPS-45-26-26-15 |

|---|---|---|

| Piston diameter | 26 mm | 45 mm |

| Rod diameter | 20 mm (synchronising) | 26 mm (synchronising) |

| Stroke | 20 mm or 50 mm | 15 mm |

| Distance measurement system | IMS (LVDT) | IMS (LVDT) |

| max. force | +/- 7 kN | +/- 33 kN |

| Mass to be moved | <= 5 kg | <= 50 kg |

| Frequency range | 600 Hz | 500 Hz |

| max. acceleration (for max. useful load) |

250 g | 150 g |

| max. supply pressure | 340 bar | 340 bar |

| max. average volume flow | 43 l/min. (at~ 80 Hz) | 70 l/min. (at~ 50 Hz) |

| Hydraulic oil | ISO VG-46 preferably synthetic | ISO VG-46 preferably synthetic |

| Ambient temperature range | -10 to +35 degrees C | -10 to +35 degrees C |

| Mass HPS | length: 408 mm Ø420 mm | length: 320 mm Ø400 mm |

| Dimensional drawings | HPS_M01_3083-3.pdf | HPS_M01_3292.pdf |

|

|