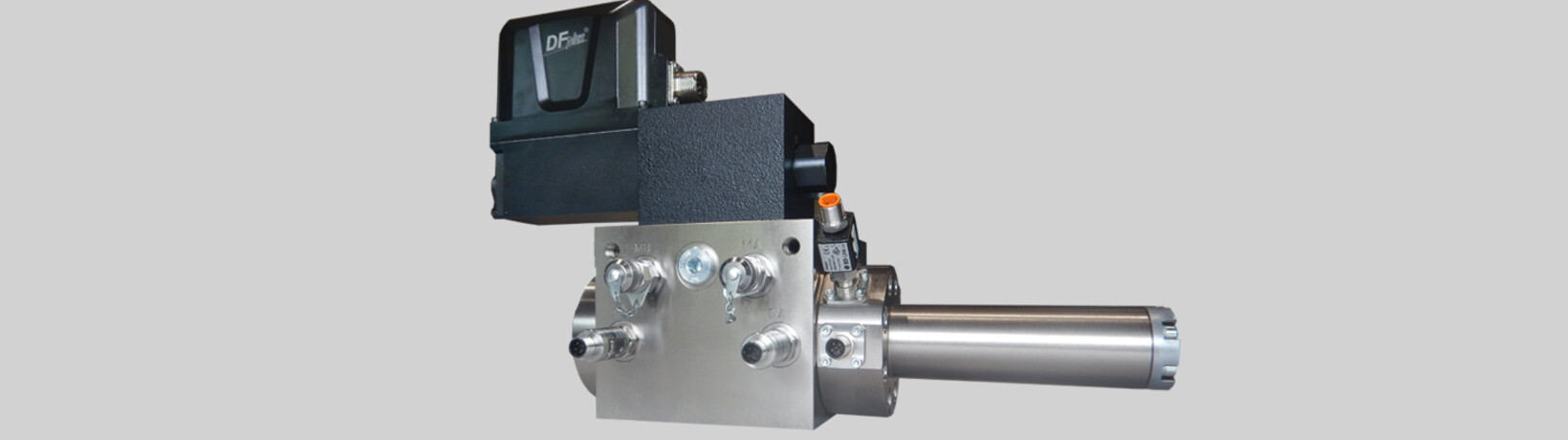

Frequency response cylinder

With the frequency response cylinder it is possible to measure the dynamics of the valves and to document them in a frequency response diagram, even if these valves do not have their own displacement transducer. The movement of the valve slide is measured indirectly by the position or speed of the very light and low-friction cylinder piston, which moves back and forth through the oil flow controlled by the valve.

The frequency response cylinder is usually used as an accessory to the servo valve test bench, which has further extensive measuring options. Together with a suitable pressure supply and our test control, it is also possible to operate the frequency response cylinder without the servo valve test bench.

Depending on the area of application, measuring the frequency response offers you various advantages:

- As a valve developer, you can directly check design improvements

- You can optimally support your customers in their selection by specifying the dynamics of their valve

- The measurement of dynamics is a targeted instrument for quality assurance in the production process

-

By measuring the dynamics, the condition of used valves can be better assessed during maintenance, thus avoiding unnecessary new purchases

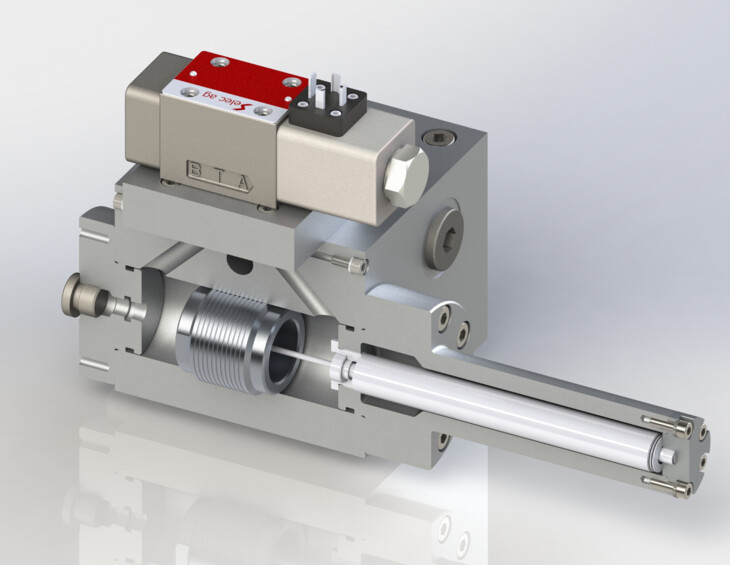

Specifications

| Piston diameter | 50 mm |

| Piston surface | 19.6 cm² |

| Maximum stroke | 60 mm |

| Used stroke | 50 mm |

| Test pressure | up to 350 bar |

| Connection hole pattern | NG4, NG6 und NG10 |

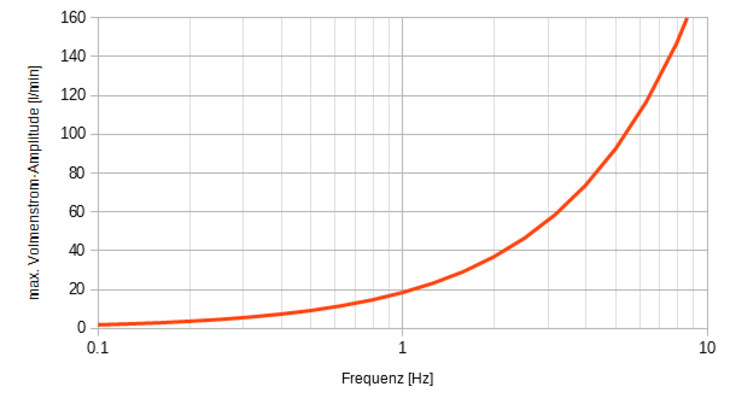

Limits of use

Due to the limited volume of the cylinder, very low frequencies may no longer be tested, depending on the valve flow rate. When measuring the frequency response, the high frequencies are usually interesting. Should your application nevertheless require a measurement outside the specification shown here, we will design the frequency response cylinder according to your requirements.

The position measuring system used is specially designed for very high frequencies and is therefore suitable for testing very dynamic control or servo valves.